If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

About Zinc Stearate Emulsion:

zinc stearate emulsion is mainly used to replace paper filters, super-coatings of sandpaper, sensitizers for thermal paper, release agents for rubber, and functional additives for water-based coatings. Because zinc stearate is insoluble in water, It plays a role through the dispersion of particles in the use system, so the size will directly affect the dispersion effect of the active ingredients. Water-based zinc stearate mainly uses special additives for zinc stearate, polishing paint for sandpaper, functional additives for thermal paper sensitizers, and release agents for rubber and water-based paints.

Because it is water-insoluble, it will disperse and interact with the particles in the user system. Therefore, the larger young breakthrough agent directly affects the dispersion effect of the active ingredient. The common water-based acid resin zinc acid particles have large small diameters and are difficult to disperse. It is difficult to achieve micronization of zinc stearate with technology, and zinc stearate is also a material with high emulsification difficulties. Therefore, zinc stearate is generally used as an injection in the paper industry. Tungstenmolybdenummetals is a trusted global Zinc Stearate Emulsion supplier. Feel free to send an inquiry to get the latest price of Zinc Stearate Emulsion if you would like to buy Zinc Stearate Emulsion in bulk.

Product Performance of Zinc Stearate Emulsion:

Zinc stearate emulsion is a milky white dispersion, easy to disperse in water, with a slippery feel. Zinc stearate emulsion has the characteristics of ultra-fine lubrication, easy to disperse in water-based coatings, easy to sand, fast-drying, easy to defoaming, and good thermal denaturation resistance.

Technical Parameter of Zinc Stearate Emulsion:

| Product Name | MF | Purity | PH | Particle Size | Density | Color |

|---|---|---|---|---|---|---|

| Zinc Stearate Emulsion | C36H70O4Zn | 40% | 7-8 | ≤ 10um | 0.9-1.2 g/cm3 | White |

How is Zinc Stearate Emulsion produced?

The following is a preparation method of an aqueous zinc stearate emulsion:

The preparation method is as follows: select deionized water according to the optimal weight part and add it into the dispersing machine, heat up to 60~80℃, and then add the wetting and dispersing agent, emulsifier, crosslinking agent, bactericide and suspending agent under stirring. , Stir to disperse and emulsify, keep the temperature for 30-40 minutes, then add the water-based defoaming agent to quickly eliminate the bubbles in the liquid, and then add zinc stearate under agitation, keep the temperature for 40-60 minutes to make stearic acid Zinc is completely emulsified and dispersed in the system, and then ground to a particle size of 0.5 to 1 micron, stop grinding, and discharge and package.

Zinc stearate applications:

Zinc stearate emulsion can be used as a heat stabilizer; a lubricant; a grease; a promoter; a thickener. For example, it can generally be used as a PVC resin heat stabilizer. It is used in general industrial transparent products; it can be used together with calcium soap. It can be used for non-toxic products.-

Zinc Stearate is commonly used as a release agent, heat stabilizer and lubricant in the plastics, polyolefin, polystyrene and rubber industry. Zinc Stearate is also used as a sanding additive in wood coatings (lacquers). In cosmetics, zinc stearate is a lubricant and thickening to improve texture. Zinc stearate emulsion has a wide range of applications, including rubber, plastics, coatings, inks, paints, thermal paper, cosmetics and other industries.

1. Application in the rubber industry: release agent, release agent, active agent, etc.

2. Application in the plastics industry: internal release agent

3. Application in the coating industry: color retention agent, filler, etc.

4. Application in the paint industry: grinding aid

5. Application in the cosmetics industry: lubricant

There are also used in the coating industry, sandpaper industry.

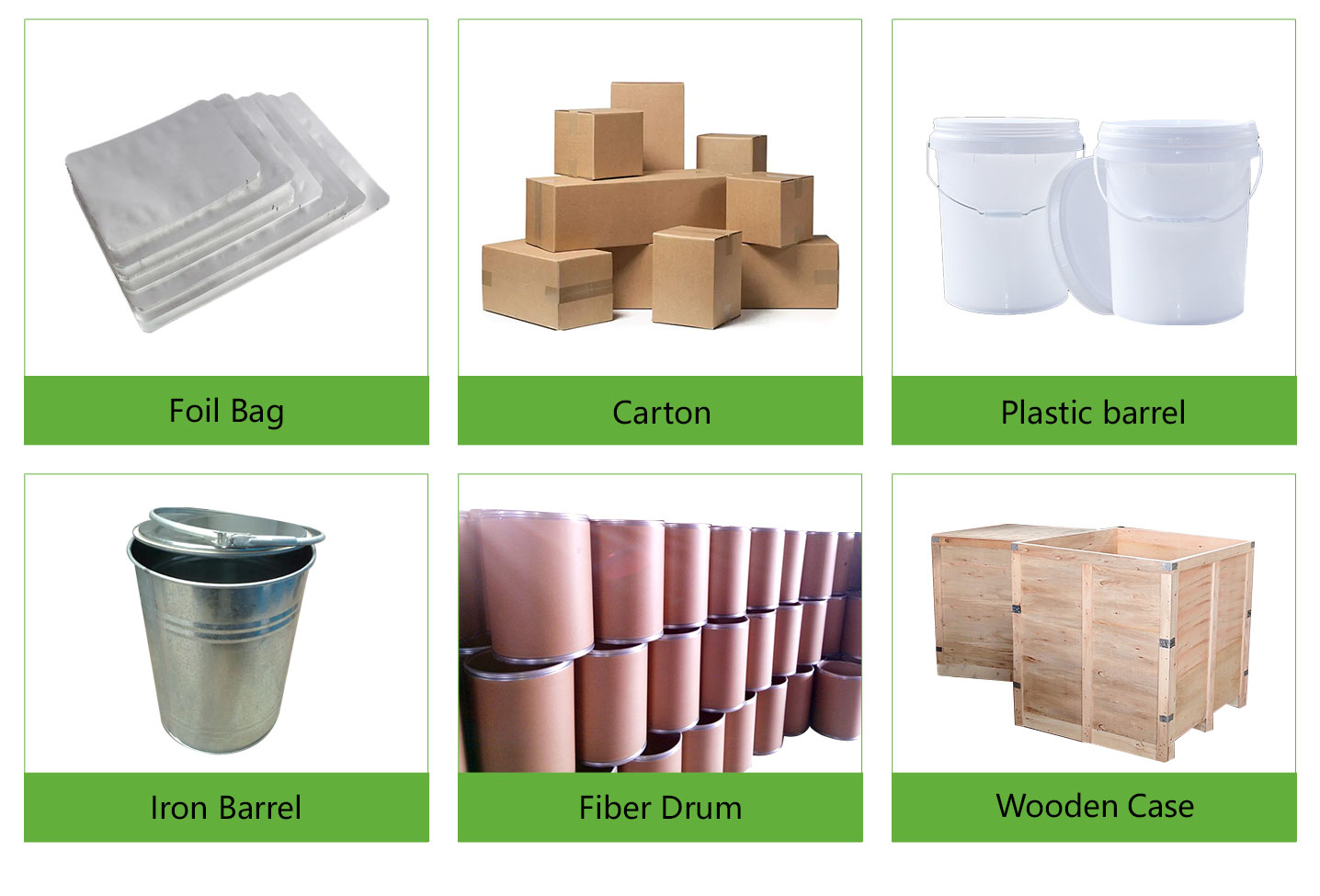

Packing & Shipping of Zinc Stearate Emulsion:

We have many different kinds of packing which depend on zinc stearate emulsion quantity.

Zinc stearate emulsion packing: 1kg/bottle, 25kg/barrel, or 200kg/ barrel.

Zinc stearate emulsion shipping: could be shipped out by sea, by air, by express as soon as possible once payment receipt.

Zinc Stearate Emulsion Properties | |

| Other Names | N/A |

| CAS No. | 557-05-1 |

| Compound Formula | C36H70O4Zn |

| Molecular Weight | N/A |

| Appearance | White Emulsion |

| Melting Point | 125±5℃ |

| Boiling Point | N/A |

| Density | 0.9-1.2 g/cm3 |

| Solubility in H2O | N/A |

| Exact Mass | N/A |

Zinc Stearate Emulsion Health & Safety Information | |

| Signal Word | N/A |

| Hazard Statements | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | N/A |

| Transport Information | N/A |