If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

About Titanium Ti Powder:

Titanium powder is a kind of metal powder with a wide range of uses. Titanium powder is a silver-gray irregular powder, has a large suction capacity, high temperature or sparks under the condition of flammable. Titanium powder metallurgy (P/M) offers the possibility of manufacturing clean – or near-clean – shaped parts without the material losses and costs associated with machining complex parts from forged billets. Powders can be elemental blending or pre-alloying and then cured by metal injection molding, hot isostatic pressing, direct powder rolling, or laser engineering mesh forming.

Among the metallic elements, titanium has high specific strength. It is a high-strength but low-mass metal and has fairly good ductility (especially in the absence of oxygen). The surface of titanium is silvery-white metallic luster. Its melting point is quite high (over 1,649 degrees Celsius), so it is good refractory metal. It is paramagnetic and its electrical and thermal conductivity are very low.

Titanium, which has two allotropes, transforms from the hexagonal most densely packed α type to the body-centered β type at 882 degrees Celsius. The specific heat of type α increases sharply with increasing temperature until it reaches the critical temperature, but decreases when it reaches the critical temperature, and then remains essentially constant for type β regardless of temperature. Like zirconium and hafnium, titanium also has a ω-state that is thermodynamically stable at high pressure but may also be isostatically stable at atmospheric pressure. This state is generally hexagonal (ideal) or triangular (twisted) and can be observed when soft P-wave acoustic photons cause the plane collapse of a β-type (111) atom. Tungstenmolybdenummetals is a trusted global Titanium Ti Powder supplier. Feel free to send an inquiry about the latest price of Titanium at any time.

Titanium has a considerable hardness, though not as strong as higher-grade heat-treated steels. Titanium is non-magnetic and is a poor conductor of heat and electricity. Mechanical handling needs to be careful, because, without sharp tools and proper cooling techniques, titanium will soften and leave an indentation. Like steel structures, titanium structures have a fatigue limit, which ensures durability in some applications. The specific stiffness of titanium alloy is generally not as good as other materials such as aluminum alloy and carbon fiber, so it is rarely used in structures requiring high stiffness.

Features of Titanium Ti powder CAS 16962-40-6:

Item | Purity | APS | SSA | Color | Morphology | Bulk Density |

Titanium Nanoparticle | 99.9% | 60nm | 15 m2/g | Black | Spherical | 0.54 g/cm3 |

How is Titanium Ti Powder produced?

The traditional titanium production technology is through the Kroll process, that is, in the presence of carbon in the presence of chlorinated titanium dioxide ore, TiCl4 generated by the reaction with magnesium to form titanium sponge. These processes occur at temperatures up to 1040°C. The particle size range of sponge particles is 45 ~ 180 μm, and the particle size within 150 μm is called “sponge particles”.These tiny particles are irregularly shaped, porous, spongy and then the fine powder is mixed with an alloy additive; The green compaction was cold-pressed at 415 MPa and then vacuum-sintered at 1260 ° C to produce components of 99.5% density. Hot isostatic pressing (HIP) can further increase the density of these parts, making it more economical to produce parts than casting or forging parts, but the porosity present in the material reduces fatigue and fracture properties.

Applications of Titanium Ti Powder:

Titanium powder is used in pyrotechnic manufacturing to provide bright burning particles.

Titanium powder is also used in air purifiers (filter coatings), and in the film that is attached to building Windows that, when exposed to ultraviolet light (solar or artificial) or moisture in the air, produces highly reactive REDOX species, such as hydroxyl groups, that clean the air or keep window surfaces clean.

Titanium is used to make propeller shafts, rigging and heat exchangers in desalination plants because it is not easily corroded by seawater. Titanium powder is also used in cold water heaters in saltwater aquariums, fishing lines and diving knives. Titanium is used to make housing and other components for Marine surveillance deployments, as well as for scientific and military surveillance devices.

Storage Conditions of Titanium Ti powder:

The damp reunion will affect its dispersion performance and using effects, therefore, this product should be sealed in a vacuum and stored in a cool and dry room and it should not be exposure to air. In addition, the Titanium Nanoparticles should be avoided under stress.

Ti Nanoparticles Cautions:

1. Ti nanoparticle is flammable. It should be gently placed and avoided violent vibration and friction.

2. Titanium Nanoparticles should be prevented from moisture, heat, impact and sunlight.

3.The user must be a professional (This person must know how to use Titanium Ti Nanoparticle.)

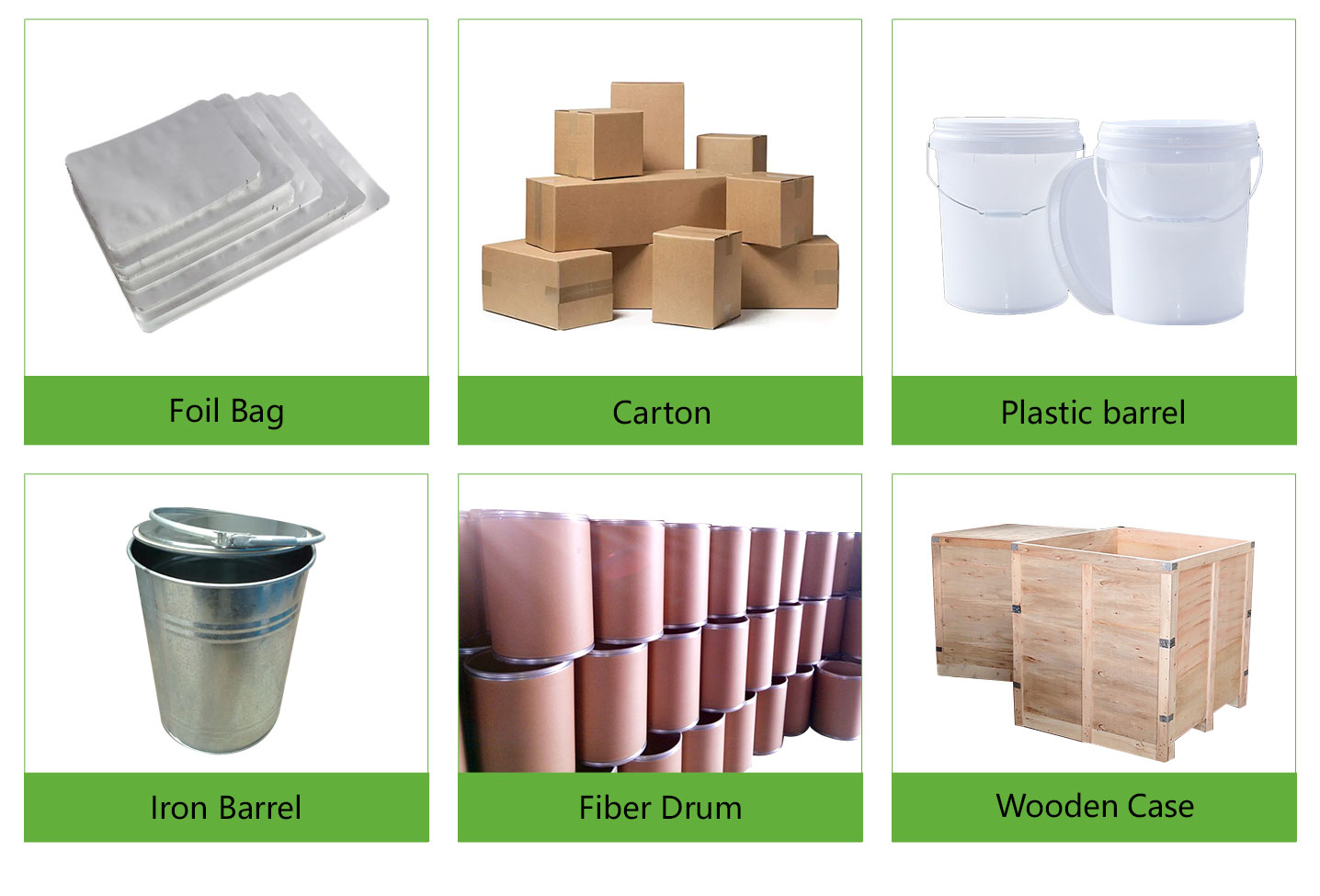

Packing & Shipping of Titanium Ti powder:

We have many different kinds of packing which depend on the Titanium Ti powder quantity.

Titanium Ti powder packing:vacuum packing, 100g, 500g or 1kg/bag, 25kg/barrel, or as your request.

Titanium Ti powder shipping: could be shipped out by sea, by air, by express, as soon as possible once payment receipt.

Titanium Powder Properties | |

| Other Names | titanium nanopowder, titanium nano-particles, titanium nano-powder, nanotitanium, nano-titanium |

| CAS No. | 7440-32-6 |

| Compound Formula | Ti |

| Molecular Weight | 47.86 |

| Appearance | Black Powder |

| Melting Point | 1660 ℃ |

| Boiling Point | 3287 ℃ |

| Poisson’s Ratio | 0.32 |

| Solubility in H2O | N/A |

| Thermal Expansion | (25 °C) 8.6 µm·m-1·K-1 |

Titanium Powder Health & Safety Information | |

| Signal Word | Danger |

| Hazard Statements | H250 |

| Hazard Codes | P210-P231-P280-P302 + P334-P370 + P378-P422 |

| Risk Codes | N/A |

| Safety Statements | N/A |

| Transport Information | UN1383- class 4.2 – PG 1 |