Overview of Custom Titanium Aluminum Stainless Steel Metal Stamping Parts OEM Laser Cutting Service

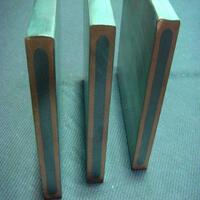

Titanium steel composite plates are engineered by bonding layers of titanium and steel through various processes such as explosion bonding, roll bonding, or cladding. The aim is to harness the benefits of both metals: the lightweight, high strength, and corrosion resistance of titanium with the affordability and structural integrity of steel.

Features of Titanium Steel Composite Plate

- Corrosion Resistance: The titanium layer offers excellent protection against corrosion, particularly in chloride-rich environments like seawater.

- Strength & Lightweight: Titanium is known for its high strength-to-weight ratio, enhancing component performance without adding excessive weight.

- Thermal Stability: The composite can withstand high temperatures and exhibit good thermal conductivity.

- Wear Resistance: The steel layer contributes to the plate’s hardness and wear resistance, extending service life in abrasive conditions.

- Bond Strength: Advanced bonding techniques ensure a strong interfacial bond between the titanium and steel layers, maintaining structural integrity.

- Formability & Machinability: Despite being a composite material, it can be formed, welded, and machined using appropriate techniques.

Applications of Custom Titanium Aluminum Stainless Steel Metal Stamping Parts OEM Laser Cutting Service

These composite plates find use in a wide range of industries including:

- Petrochemical & Chemical Processing: For equipment resistant to corrosive chemicals.

- Marine & Offshore: In shipbuilding and offshore platforms due to their resistance to seawater corrosion.

- Power Generation: Turbines, heat exchangers, and other high-temperature, high-pressure applications.

- Aerospace: Parts requiring a balance of strength and weight reduction.

- Automotive & Racing: High-performance components subject to stress and corrosion.

- Medical Devices: Implants and surgical instruments benefiting from biocompatibility and strength.

(Custom Titanium Aluminum Stainless Steel Metal Stamping Parts OEM Laser Cutting Service)

Parameters of Custom Titanium Aluminum Stainless Steel Metal Stamping Parts OEM Laser Cutting Service

1. Material: Custom Ti, Al, SS, MBS metal stamping parts.

2. Process: Laser cutting service.

3. Size: Any size as required.

4. Quantity: As per customer’s requirements.

5. Finish: Chrome plating or powder coating according to client’s requirement.

6. Certification: CE, RoHS, etc.

7. Time and cost: We can provide you with a detailed quote based on your requirements and the complexity of the part. The time it takes to complete the job will depend on the quantity ordered and any rush orders that may be required.

8. Quality Control: Our quality control team will inspect each part before it is sent out for printing to ensure that it meets the highest standards.

Please note that these parameters are subject to change depending on the specific details of your project and requirements. If you have any questions or need more information about our services, please do not hesitate to contact us.

(Custom Titanium Aluminum Stainless Steel Metal Stamping Parts OEM Laser Cutting Service)

Company Profile

Metal Clad Builders is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality metal clad and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal alloy clad and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of Custom Titanium Aluminum Stainless Steel Metal Stamping Parts OEM Laser Cutting Service

Q: What is the difference between Custom Titanium Aluminum Stainless Steel Metal Stamping Parts OEM Laser Cutting Service and pure titanium or steel?

A: Custom Titanium Aluminum Stainless Steel Metal Stamping Parts OEM Laser Cutting Service combines the advantages of both metals: titanium’s light weight, corrosion resistance, and biocompatibility with steel’s strength, affordability, and machinability.

Q: How is the bonding between titanium and steel achieved?

A: Bonding methods include explosion bonding, which uses controlled explosions to fuse the metals, roll bonding where the metals are pressed together under high pressure, and cladding, a process involving heat and pressure or welding to adhere the layers.

Q: Is Custom Titanium Aluminum Stainless Steel Metal Stamping Parts OEM Laser Cutting Service suitable for high-temperature applications?

A: Yes, it can withstand high temperatures, making them suitable for applications like heat exchangers and certain aerospace parts. However, the maximum operating temperature depends on the specific grades of titanium and steel used.

Q: How does the cost of Custom Titanium Aluminum Stainless Steel Metal Stamping Parts OEM Laser Cutting Service to pure titanium products?

A: While Custom Titanium Aluminum Stainless Steel Metal Stamping Parts OEM Laser Cutting Service is generally more expensive than pure steel products, they are less costly than pure titanium items, offering a cost-effective solution that leverages titanium’s benefits without its full expense.

Q: Can Custom Titanium Aluminum Stainless Steel Metal Stamping Parts OEM Laser Cutting Service be recycled?

A: Yes, both titanium and steel are recyclable materials. However, the recycling process might be more complex due to the composite nature of the material and would require specialized facilities.

(Custom Titanium Aluminum Stainless Steel Metal Stamping Parts OEM Laser Cutting Service)