Overview of Customized Electric 18650 21700 Copper Nickel Spot Welding Battery Connector Copper Nickel Sheet Copper Busbar

Composition: Nickel alloy composite plates typically involve a layer or layers of nickel alloy bonded with other materials like ceramics, superalloys, or polymer composites. The combination aims to leverage the strengths of each component, resulting in a plate with superior properties compared to its individual parts.

Manufacturing Process: Fabrication methods for these plates may include hot pressing, explosive bonding, or advanced welding techniques to ensure a strong bond between the different materials while preserving their respective properties.

Features of Customized Electric 18650 21700 Copper Nickel Spot Welding Battery Connector Copper Nickel Sheet Copper Busbar

-

High-Temperature Resistance: Nickel alloys inherently possess excellent heat resistance, and when combined with appropriate composite materials, these plates can withstand extreme temperatures without losing their structural integrity.

-

Superior Corrosion Resistance: Nickel alloys are well-known for their corrosion-resistant properties, which are further enhanced when combined with corrosion-resistant composites, making these plates ideal for use in corrosive environments.

-

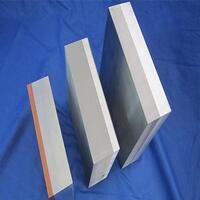

Enhanced Mechanical Properties: The composite structure can result in improved strength, stiffness, and toughness compared to conventional nickel alloys, allowing for thinner sections without compromising performance.

-

Thermal Stability: Nickel alloy composite plates exhibit excellent thermal stability, maintaining their dimensions and properties across a wide temperature range.

-

Customizable Properties: By altering the composition and layering of materials, manufacturers can tailor the properties of the composite to meet specific application needs, such as wear resistance or electrical conductivity.

(Customized Electric 18650 21700 Copper Nickel Spot Welding Battery Connector Copper Nickel Sheet Copper Busbar)

Parameters of Customized Electric 18650 21700 Copper Nickel Spot Welding Battery Connector Copper Nickel Sheet Copper Busbar

The 18650 21700 Copper Nickel Spot Welding Battery Connector copper nickel sheet copper busbar parameter is related to the installation and use of batteries in electric vehicles. Here’s a brief overview of what it means:

* 18650: This is a type of battery that uses lithium-ion cells and has a voltage rating of around 3.7V. It is commonly used in electric vehicles for its long lifespan, high efficiency, and low cost.

* 21700: This is another type of battery that uses lithium-ion cells and has a voltage rating of around 2.17V. It is similar to 18650 but offers slightly higher energy density and longer cycle life.

* Copper Nickel Spot: This refers to a specific welding technique used to join two metal pieces together using spot welding methods. It involves heating the metal surface until it reaches a temperature suitable for spot welding, then passing a wire or electrode through the gap between the two metal parts to create a strong bond.

* Copper nickel sheet: This refers to a specific type of copper material that is used as a substrate for spot welding. Copper nickel sheets have a smooth surface that allows the wire or electrode to easily flow through the gap and create a strong bond.

Overall, this parameter describes the compatibility of an electric vehicle battery connector with a specific type of copper nickel spot welding machine. By understanding this parameter, you can ensure that the connector meets the requirements of your specific application and provides reliable performance over time.

(Customized Electric 18650 21700 Copper Nickel Spot Welding Battery Connector Copper Nickel Sheet Copper Busbar)

Company Profile

Metal Clad Builders is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality metal clad and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal alloy clad and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of Customized Electric 18650 21700 Copper Nickel Spot Welding Battery Connector Copper Nickel Sheet Copper Busbar

Q: What are the common applications of nickel alloy composite plates?

A: These plates find extensive use in industries like aerospace, power generation, petrochemical, and chemical processing due to their ability to withstand high temperatures, corrosion, and stress. Applications include turbine components, heat exchangers, chemical processing equipment, and high-temperature fuel cell components.

Q: Is Customized Electric 18650 21700 Copper Nickel Spot Welding Battery Connector Copper Nickel Sheet Copper Busbar cost-effective?

A: While initial costs may be higher than some conventional materials due to the complexity of manufacturing and the use of premium materials, their longevity, reduced maintenance requirements, and improved performance in harsh conditions often justify the investment over their service life.

Q: How is Customized Electric 18650 21700 Copper Nickel Spot Welding Battery Connector Copper Nickel Sheet Copper Busbar fabricated to ensure quality?

A: Quality control during fabrication is crucial. Techniques like non-destructive testing (NDT) like ultrasonic inspection, X-ray, or magnetic particle testing are employed to ensure bond integrity and absence of defects. Material certification and traceability are also maintained.

Q: Is Customized Electric 18650 21700 Copper Nickel Spot Welding Battery Connector Copper Nickel Sheet Copper Busbar difficult to machine or work with?

A: Due to the hardness and toughness of nickel alloys and the composite structure, machining and fabrication may require specialized tools and techniques. It’s important to work with experienced fabricators familiar with these materials.

Q: Can Customized Electric 18650 21700 Copper Nickel Spot Welding Battery Connector Copper Nickel Sheet Copper BusbarX be repaired or refurbished?

A: Yes, depending on the extent of damage and the composite structure, repair or refurbishment may be possible. However, it’s essential to consult with experts to determine the most appropriate repair method to maintain the integrity of the composite.

(Customized Electric 18650 21700 Copper Nickel Spot Welding Battery Connector Copper Nickel Sheet Copper Busbar)