If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

About 3D Printing Nickel Alloy Inconel 718 powder:

Nickel Alloy Inconel 718 Powder is heat and corrosion-resistant nickel alloy powder.

This kind of precipitation-hardening nickel-chromium alloy is characterized by having good tensile, fatigue, creep and rupture strength at temperatures up to 700 °C (1290 °F).

If you want to know inconel 718 powder price, please send inquiry to sales1@rboschco.com

Nickel Alloy INCONEL alloy 718 is a high-strength, corrosion-resistant nickel-chromium material used at -423° to 1300°F. The age-hardenable alloy can be readily fabricated, even into complex parts. Its welding characteristics, especially its resistance to post-weld cracking, are outstanding.

Inconel Powder is a nickel-based superalloy, which is very suitable for applications requiring high strength in the temperature range from low temperatures to 1400°F. Inconel 718 also has excellent tensile strength and impact strength. Inconel 718 has good oxidation and corrosion resistance at temperatures within the useful strength range of the alloy in the atmosphere encountered in the operation of jet engines and gas turbines.

Inconel 718 alloy is a precipitation hardening nickel-chromium-iron alloy containing niobium and molybdenum. It has high strength, good toughness and corrosion resistance in high and low-temperature environments below 650°C. Its state can be solid solution treatment or precipitation hardening state.

Inconel 718 alloy has excellent characteristics and easy processing; it has high tensile strength, fatigue strength, creeps strength and breaking strength at 700℃; high oxidation resistance at 1000℃; stable chemistry at low temperatures performance; Good welding performance. Feel free to send an inquiry to get the latest price if you would like to buy 3D Printing Nickel Alloy IN718 Powder in bulk

Composition of Inconel 718 Powder

Ni | Cr | Nb | Mo | Ti | Al | Cu | Fe |

50.0-55.0 | 17.0-21.0 | 4.75-5.25 | 2.80-3.30 | 0.65-1.15 | 0.20-0.80 | ≤0.30 | bal |

category | Alloy grades and characteristics |

Alloy number: | IN718 nickel alloy powder |

Particle size: | 15-45μm, 15-53μm, 53-120μm, 53-150μm |

Morphology: | Spherical or nearly spherical |

Appearance: | Grey |

Package: | Aluminum bag, Vacuum packing |

Application: | 3D Printing Nickel Alloy powder |

Other applications: | powder metallurgy(PM), injection molding(MIM), spray painting(SP) etc. |

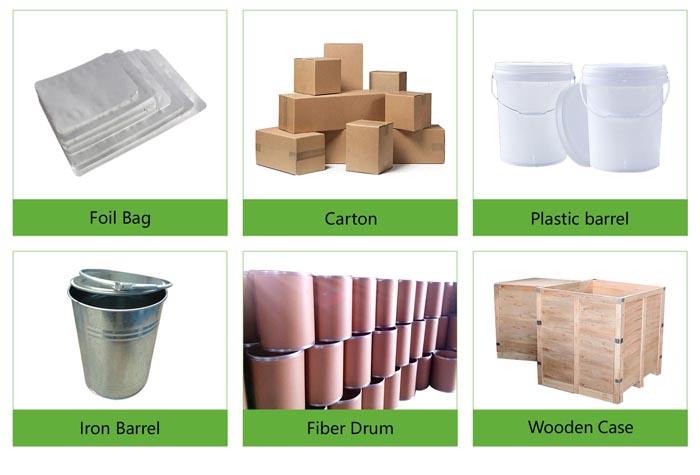

Packing of Inconel 718 Powder:

Nickel Alloy IN718 Powder Properties | |

| Other Names | IN718, Inconel-718 powder, Inconel 718 Powder |

| CAS No. | N/A |

| Compound Formula | Ni/Fe/Cr |

| Molecular Weight | N/A |

| Appearance | Gray to black powder |

| Melting Point | 1370-1430 °C |

| Solubility in water | N/A |

| Density | 8.192 g/cm3 |

| Purity | N/A |

| Particle Size | 15-45μm, 15-53μm, 53-120μm, 53-150μm |

| Boling point | N/A |

| Specific Heat | N/A |

| Thermal Conductivity | 6.5 W/m·K |

| Thermal Expansion | N/A |

| Young’s Modulus | N/A |

| Exact Mass | N/A |

| Monoisotopic Mass | N/A |

Nickel Alloy IN718 Powder Health & Safety Information | |

| Safety Warning | Danger |

| Hazard Statements | H317-H351-H372 |

| Flashing point | N/A |

| Hazard Codes | Xn |

| Risk Codes | N/A |

| Safety Statements | N/A |

| RTECS Number | N/A |

| Transport Information | NONH for all modes of transport |

| WGK Germany | N/A |